Create Solar has received a grant from the Natural Sciences and Engineering Research Council of Canada (NSERC) and Mitacs to participate in a large-scale research project led by UBC Okanagan in collaboration with the City of Kelowna.

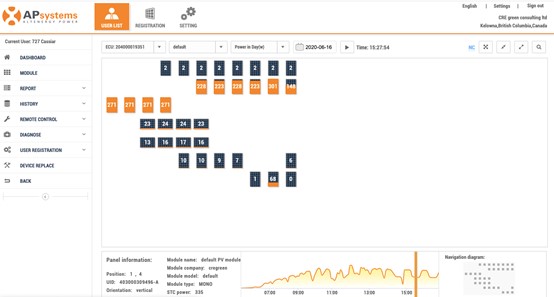

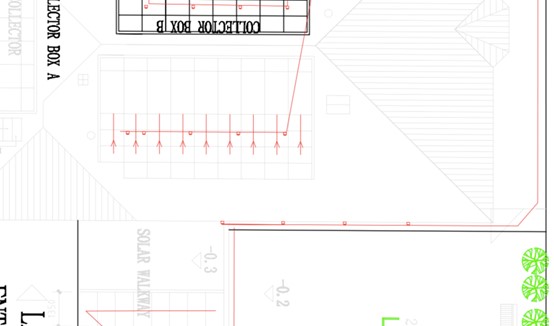

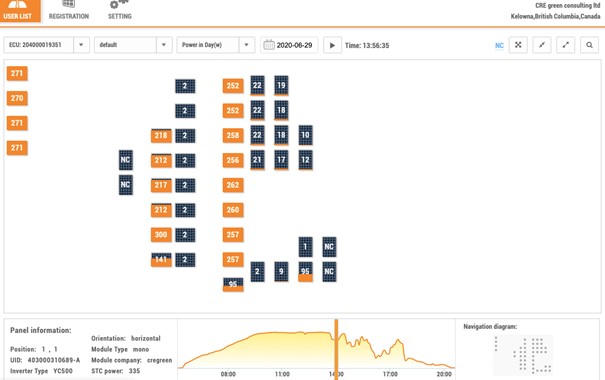

The objective of the project is to assess the feasibility of implementing solar photovoltaic systems in Kelowna, with the aim of helping the city achieve its goals for reducing greenhouse gas emissions and increasing the use of clean energy. This project includes the evaluation of the feasibility for solar energy in the region by analyzing socio-techno-economic barriers and regulatory barriers, using software and real-time operational data.

Create Solar’s team will be collaborating on this project by providing real-world operational data, contributing to the direction of the research, and contributing to the analysis of the findings. In exchange we will have access to the wealth of important solar-related information being generated specific to the Kelowna area, as well as having the inside track on becoming the developer for the many future projects will likely result from the findings of this study.